OTHER PRODUCTS

The machine has a media width of 350 mm and a print width of 250 mm, with a maximum media thickness of 3 mm. Its speed is 120 m / h, with a Japanese print head. Resolution-300 dpi. Materials such as: paper, cardboard, plastic, PU, PVC, leather, matte PVC, binding and layout paper, fabric, etc. can be used.

Pulse welding is a new technology that avoids waves and harmful radiation, saves electricity and the result is a seam with great strength and precision. With a non- automatic pressing system and heating and cooling time adjustment programmes, it makes the machine comfortable and easy to operate.

The eyelet placement machine allows for easy and fast handling of the process and the use of elements of different materials with a diameter of 6.35 mm to 18.2 mm. There are different and very convenient attachments. First drill the hole, then insert and mount the clamp with one push of the handle.

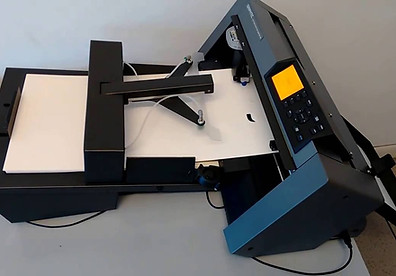

System for cutting sheet foil in large quantities. Contour cutting without operator of self-adhesive sheets, cardboard, prints, labels, business cards, etc. From 40 to 120 sheets. 3 parts: feed tray, cutting plotter and output tray.

The styrofoam cutting machine allows for the production of volumetric letters, figures and a wide range of styrofoam products. Easy to operate, this machine is made in Hungary, with a working area of 590x1230 mm and a material thickness of 145 mm. The machine works at a speed of 12 mm / sec.

The machine for welding vinyl and PVC materials is small, light, easy and convenient to operate. It has a sensor that maintains a constant temperature throughout the work process. The result is a strong and fast welding without the use of glue. The display shows the temperature and speed settings.

We offer German and Chinese thermal presses with dimensions from 38x38 cm. These machines are automatic and have electronic regulation of temperature and operating time. The maximum heating temperature is 260 degrees.

With advanced options for finishing, file sharing, and mobile printing, HP printers come with genuine HP JetIntelligence toner cartridges - fast, easy to use and multifunctional.

Wide range of printers, including compact thermal printers that meet different printing requirements. High precision and high printing speed. The machines have a beautiful and extremely functional design.